- Home

- >

- Knowledge Center

- >

- Blogs

Blogs

Sharing knowledge is key to an innovative and healthy industry! This knowledge center is therefore a central place on our website to share information. Read all about our industry in the blogs below!

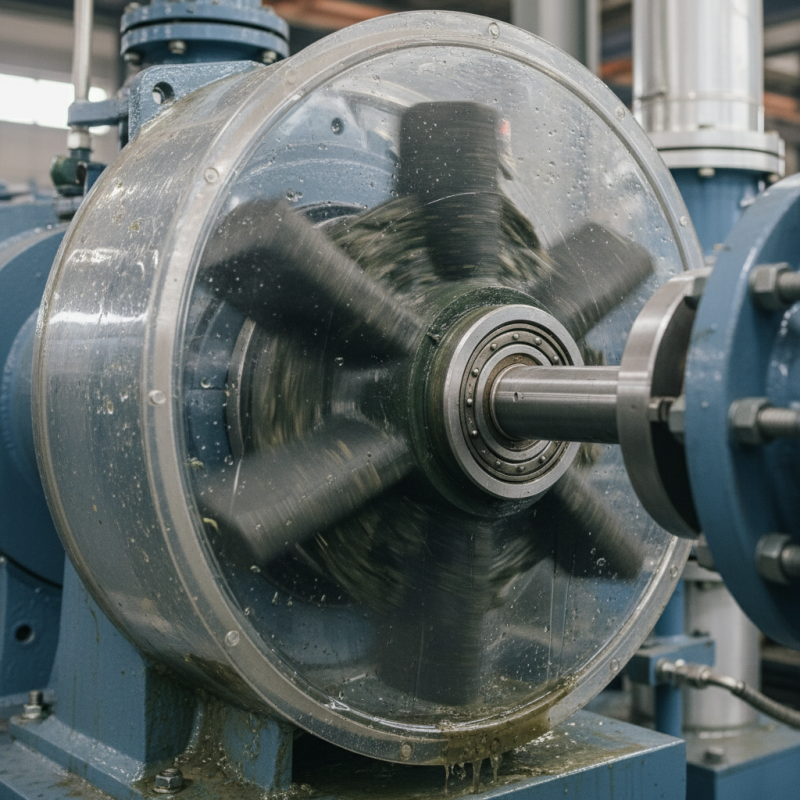

Rubber Pump Impeller Tips for Optimal Performance and Longevity?

In the world of industrial engineering, the performance and longevity of the Rubber Pump Impeller are often overlooked. Many professionals encounter issues that could be avoided with better knowledge. Expert John Smith, a renowned figure in pump technologies, once stated, "Regular maintenance and understanding of Rubber Pump Impeller mechanics can greatly enhance performance." This insight emphasizes the importance of proactive care.

Rubber Pump Impellers operate under various conditions. They endure pressure and abrasive materials daily. Their durability is key to operational efficiency, yet wear and tear can lead to significant downtime. Selecting the right materials is crucial. Small choices impact performance and longevity.

While improvements have been made, gaps remain in industry practices. Some operators neglect proper inspection routines, leading to failures. This oversight is preventable with simple adjustments. Awareness and education can bridge these gaps, ensuring that Rubber Pump Impellers perform optimally for years. Transforming approaches requires commitment; every detail matters in the quest for excellence.

Understanding Rubber Pump Impellers and Their Role in Performance

Rubber pump impellers play a crucial role in achieving optimal performance in various fluid-handling applications. These components are designed to create a flow of liquid and boost pressure in pump systems. According to industry reports, rubber impellers can exhibit performance improvements of up to 20% compared to their metal counterparts when properly maintained. Their flexibility allows them to absorb vibrations, which reduces wear and extends the lifespan of the pump.

However, not all rubber materials are created equal. The selection of the right rubber compound significantly influences the impeller’s durability and performance. A study showed that impellers made with high-quality rubber can last 30% longer than those made with standard materials. Yet, many operators often overlook this aspect. They might make decisions based solely on cost, ignoring long-term benefits. This short-sighted approach can lead to frequent maintenance issues and higher operational costs.

Periodic inspection and maintenance are essential. Even the best rubber compounds can degrade over time due to environmental factors. Operators should consider checking for cracks, wear, or discoloration. These indicators can signal the need for replacement. Ignoring such signs can result in decreased efficiency and potential system failure. Regularly assessing the condition of rubber impellers can ensure maximum performance and longevity.

Rubber Pump Impeller Performance Analysis

Factors Influencing the Longevity of Rubber Pump Impellers

Rubber pump impellers play a critical role in effective fluid movement across various applications. Factors like material quality and operating environments significantly affect their lifespan. Heat build-up during operation often leads to wear. Inadequate cooling systems can compound this issue. Regular maintenance checks are essential to identify and rectify issues before they escalate. Neglecting small problems can lead to costly repairs or replacements.

Chemical compatibility is another crucial factor. Certain fluids can degrade rubber materials. Using incompatible substances may shorten the impeller’s life. Proper selection based on composition is vital. Operators should consider the specific characteristics of each fluid. Additionally, mechanical stress from misalignment can cause premature failure. Aligning pumps and motors correctly can minimize this threat.

Environmental conditions also matter. Extreme temperatures and abrasive particles can quickly wear out rubber. It's important to monitor surroundings. Protective measures, such as filtration systems, can shield against abrasive elements. Investing time in understanding these factors ensures better performance. Reflection on past experiences of failures can provide valuable lessons. Each small detail contributes to the overall longevity and efficiency of rubber pump impellers.

Best Practices for Maintaining Rubber Pump Impellers

Maintaining rubber pump impellers is crucial for optimal performance. Regular inspection can prevent unexpected breakdowns. Research indicates that 80% of pump failures stem from impeller issues. Small cracks or abrasions can lead to inefficiencies. These imperfections can increase operational costs significantly.

Proper lubrication is essential. It minimizes wear and tear. Industry studies show that pumps with adequate lubrication can last 30% longer. However, over-lubrication can cause more harm than good. It may attract dirt and debris, negatively impacting function. Regular cleaning is also vital.

Environmental conditions can affect impeller longevity. High temperatures or chemical exposure can degrade rubber. Implementing protective measures can help extend service life. Surprisingly, many operators neglect these factors. Focusing on a proactive maintenance approach can yield long-term benefits. Optimal performance often requires small adjustments and consistent care.

Common Issues and Troubleshooting Tips for Rubber Pump Impellers

Rubber pump impellers play a crucial role in fluid transfer. However, they are not immune to issues. A common problem is wear and tear. If you notice reduced performance, it might be time to inspect the impeller. Check for cracks or deformations. These can lead to inefficiencies and breakdowns.

Clogs are another frequent issue. Foreign particles can obstruct the impeller. Regular cleaning is essential for optimal functioning. Consider flushing the system periodically. This reduces the risk of debris buildup. Often, operators skip this step, leading to future complications.

Another point to reflect on is vibration. Excessive vibration indicates imbalance. This can stem from misalignment or damage. It may seem minor but can escalate. Regular inspections can help catch these issues early. Ignoring them could lead to major repairs down the line.

Selecting the Right Rubber Material for Optimal Pump Performance

Choosing the right rubber material for pump impellers can greatly enhance performance. Different types of rubber offer different properties. For example, natural rubber provides excellent elasticity and resilience. However, it may not withstand high temperatures or aggressive chemicals.

Synthetic rubbers, like nitrile or EPDM, have their advantages too. Nitrile is resistant to oils and fuels. EPDM, on the other hand, excels in heat and ozone resistance. This can lead to longer life and reduced maintenance. Still, every rubber type has limitations. An unsuitable choice can lead to premature wear or even failure.

It’s crucial to consider the application. Will the pump be exposed to harsh chemicals? Is temperature control essential? Understanding the operating environment can guide your material selection. Reflecting on past choices can help. Sometimes, minor adjustments in material can yield better results. Pay attention to these details. They are the key to optimal pump performance.

Rubber Pump Impeller Tips for Optimal Performance and Longevity

| Rubber Material | Durometer (Shore A) | Temperature Resistance (°F) | Chemical Resistance | Application Suitability |

|---|---|---|---|---|

| Nitrile (NBR) | 70 | -40 to 250 | Oil, Fuel | General Purpose |

| Viton (FKM) | 75 | -15 to 400 | Acids, Fuels | High Temperature |

| EPDM | 70 | -40 to 250 | Ozone, Weather | Water Service |

| Silicone | 60 | -67 to 450 | Limited | Food Grade |

| Polyurethane | 85 | -40 to 190 | Oils, Abrasives | Heavy Duty |